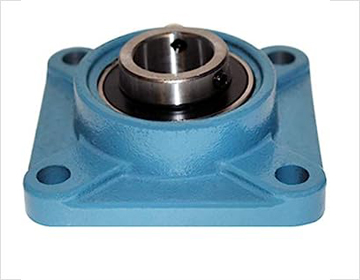

Pillow Block Bearing

Pillow Block Range

A Pillow Block Bearing Housing (also known as a pillow block housing) is a type of mounting bracket that provides support to a rotating shaft. It usually consists of a bearing housed within a mounting block, which can be bolted to a surface. The bearing housing allows the shaft to rotate smoothly while being securely supported. JAYCO Engineeering (india) provides the design & manufacture of Pillow Block in a variety of materials both standard and bespoke in design.

Download BrochurePillow blocks, also known as plummer blocks, are specialized bearing units that house a bearing within a sturdy casing. These units consist of a deep groove ball bearing, sealed on both sides, and a robust housing designed to provide excellent support and stability.

Composition:

The design of pillow blocks includes a crowned ball bearing housed within a hollow, ball-shaped casing. This configuration compensates for slight misalignments, ensuring optimal performance. The inner ring of the bearing is secured to the shaft using set screws or grub screws. Alternative fastening methods include eccentric collar lockings or adapter sleeve lockings, providing versatile options for securing the bearing in place.

Principle:

Pillow blocks function on the same technical principles as other bearing units. They ensure smooth and efficient rotation of shafts while accommodating misalignments and providing essential support. Key aspects such as tolerances, lubrication, fits, and mounting techniques are consistent with those of standard bearing units.

Application:

Pillow blocks are extensively used in mechanical engineering to support rotating shafts. They feature a machined base with two mounting holes, making them ideal for horizontal mounting on flat surfaces. Due to their robust construction, pillow blocks offer the highest load capacity among all housing types, ensuring reliable performance under heavy loads.

Frequently Asked Questions

Pillow blocks, also known as plummer blocks, are bearing housings that provide support for a rotating shaft with the help of compatible bearings and various components. They are designed to ensure smooth and efficient rotation while accommodating misalignments.

Pillow blocks are widely used in mechanical engineering to support rotating shafts. They are commonly found in conveyor systems, agricultural equipment, industrial fans, and other machinery that requires reliable shaft support.

Pillow blocks are typically made from materials such as cast iron, steel, or aluminum. The bearings within the pillow blocks can be made from various materials, including steel, ceramic, or plastic, depending on the application requirements.

Pillow blocks have a machined base with two mounting holes, allowing them to be securely fastened to a flat surface. They are particularly suitable for horizontal mounting and can be easily installed and maintained.

High Load Capacity: Pillow blocks are designed to withstand significant radial and axial loads, making them suitable for heavy-duty applications.

Ease of Installation: The design allows for easy mounting and maintenance, reducing downtime and operational costs.

Versatility: Available in various sizes and configurations, pillow blocks can be tailored to meet specific application requirements.

Pillow blocks can house different types of bearings, including plain bearings, ball bearings, roller bearings, and needle-roller bearings. The choice of bearing type depends on the specific application and load requirements.

Pillow blocks are designed with a crowned ball bearing and a hollow, ball-shaped housing that compensates for slight misalignments. This ensures optimal performance and reduces the risk of premature bearing failure.

Pillow blocks require regular lubrication to ensure smooth operation and prevent wear. The frequency of maintenance depends on the application and operating conditions. Some pillow blocks come with internally lubricated bearings that require minimal maintenance.